Lean Six Sigma is a management approach and method that endeavors to eliminate any wasteful use of resources plus defects in production processes so as to improve employee and company performance.

Fundamentals of Lean Six Sigma and TQM

Fundamentals of Lean Six Sigma and TQM

Lean Six Sigma and Recognize Phase

Lean Six Sigma and Recognize Phase

Define and Measure Phase

Define and Measure Phase

Analyse Phase

Analyse Phase

Improve Phase, Control Phase and TQM

Improve Phase, Control Phase and TQM

Lean Six Sigma in quality management is perfect for anyone eager to drive positive change in their organization. this course will equip you with valuable skills to streamline processes, reduce waste, and elevate quality. It's a fantastic opportunity for professionals at all levels who are passionate about making impactful improvements and achieving operational excellence.

Graduate

The growth percentage of Lean Six Sigma can vary based on specific industry reports and market analyses. Based on general market trends and industry insights, Lean Six Sigma adoption and growth could see an annual growth rate of 10% to 20% by 2030.

Oversees the quality assurance processes, ensuring that products and services meet established standards and customer expectations.

Analyzes current business processes, identifies areas for improvement, and implements strategies to enhance efficiency and effectiveness.

Advises organizations on best practices for achieving operational excellence through process optimization and continuous improvement.

Plans, executes, and oversees projects, ensuring they are completed on time, within scope, and within budget while meeting quality standards.

Focuses on ongoing improvements in business processes by implementing Lean, Six Sigma, and other methodologies to enhance productivity and reduce waste.

Ans : Lean Six Sigma is a methodology that combines Lean Manufacturing principles and Six Sigma techniques to improve processes, reduce waste, and enhance quality. Lean focuses on eliminating non-value-added activities, while Six Sigma aims to reduce defects and variability using data-driven approaches.

Ans : Total Quality Management (TQM) is a comprehensive management approach that seeks to improve quality and performance across an organization. TQM emphasizes customer satisfaction, continuous improvement, and employee involvement to achieve long-term success.

Ans : Lean Six Sigma and TQM complement each other by integrating Lean's focus on process efficiency and waste reduction with TQM's emphasis on continuous improvement and customer satisfaction. Together, they provide a holistic approach to achieving high-quality standards and operational excellence.

Led by certified Lean Six Sigma experts

Practical, hands-on training

Online and on-campus learning options

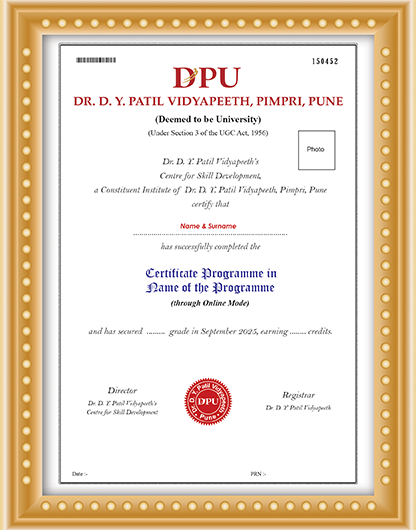

Recognized certification upon completion

Lean Origin, Lean Evolution, Six Sigma Origin, Six Sigma Evolution, Lean & Six Sigma Definitions and Terminologies, Quality Gurus

Leadership and its types, Enterprise Leadership responsibilities, Change Management,

Six Sigma Roles and Responsibilities: Executive Leadership (e.g., CEO, Senior Management), Champions, Master Black Belts, Black Belts, Green Belts, Yellow Belts

Key Aspects of Operation Management: Production Planning and Control, Project Management.

Supply Chain Management, Quality Management, Continuous Process Improvement

Lean, Six Sigma, TQM, TPM, ISO

ROI, Payback Period, Time Value of Money, Cost of Quality, Cost of Poor Quality

Communication, Team formation, Team Facilitation, Team Dynamics, Teamwork, Leadership Support, Implementing Suggestion Systems, Forming Cross-Functional Teams, Benefits of Employee Involvement.

Types of Benchmarking, Steps in Benchmarking, Benefits of Benchmarking, HEART Framework, Applying the HEART Framework.

Core Principles of TPS (Elimination of Waste, Continuous Improvement, Respect for People), Pillars of TPS, Additional Elements of TPS, Implementation and Benefits

Value, Value Stream, Pull, Flow, Perfection, Muda (Waste), Muri (Overburden), Mura (Unevenness).

TIMWOOD (T – Transport, I – Inventory, M – Motion, W – Waiting, O – Overproduction, O - Over processing, D - Defects

DMAIC: Define, Measure, Analyze, Improve, Control, DMADV: Define, Measure, Analyze, Design, Verify, Comparison of DMAIC and DMADV

Identify Stakeholders, Analyze Stakeholder Interests, and Influence, Critical to Requirement (CTR), Integrating Stakeholder Analysis and CTR

Components of the Balanced Scorecard, Cost of Poor Quality.

Voice of the Customer (VOC), Steps in VOC, Benefits of VOC,

Quality Function Deployment (QFD), Key Components of QFD, Benefits of QFD.

Affinity Diagram and its application. Categories of Kano Model, Steps to Use the Kano Model, Benefits of Kano Model, RACI Matrix

Categories in Kano Analysis, Steps to Conduct Kano Analysis,

Steps to Convert VOC to CTQ, Detailed Process

Example Process Map: Order Fulfillment

What is process and types of process mapping? Steps to Create a SIPOC Diagram

Steps to Conduct a SIPOC Analysis

Steps in Process Door Analysis, Benefits of Process Door Analysis.

Components of a Project Charter, Phases of a Project Charter, Project Tracking, Key Elements of Project Tracking, Tools for Project Tracking, Example of Project Tracking Process,

Hands on Experience to develop project charter.

Normal Distribution, Standard Normal Distribution, Other Types of Data Distribution, Identifying Data Distribution,

Types of Data, Methods of Data Collection, Sampling Strategy and Sampling, Conclusion,

Descriptive Statistics, Inferential Statistics, Probability Introduction to Minitab, Getting Started with Minitab, Basic Analyses in Minitab

Introduction to RTY, DPU, DPO, DPMO. Concepts of RTY, DPU, DPO, DPMO

RTY (Rolled Throughput Yield), DPU (Defects Per Unit), DPO (Defects Per Opportunity), DPMO (Defects Per Million Opportunities)

Measurement System Analysis, Key Concepts of MSA, Importance of MSA, Conducting a Gage R&R Study,

Box-Cox Transformation, Johnson Transformation

Cause-and-Effect Diagram (Ishikawa or Fishbone Diagram), Check Sheet (Tally Sheet), Control Charts, Histogram, Pareto Chart, Scatter Diagram, Stratification (or Flow Chart)

Risk Priority Number, Gap Analysis, 5 Why Analysis

(FMEA), Risk Priority Number (RPN), Gap Analysis, 5 Why Analysis

Key Concepts, Steps to Calculate Process Capability, Interpretation of Capability Indices

Key Concepts, Types of Hypothesis Tests, Example of Hypothesis Testing

1-sample t-test (Purpose, Use case, Assumptions)

2-sample t-test (Independent t-test)

1-way ANOVA (Analysis of Variance), Z-test

1-Proportion Test, Example, Hypotheses

2-Proportion Test, Example, Hypotheses

Chi-Squared Test, Example,

Variance Test, Mann-Whitney Test (U Test), Mood’s Median Test, One-Sample Sign Test

Correlation, Definition, Pearson's Correlation Coefficient

Introduction and conceptualization with Example

Key Concepts, The Model, Steps in Multiple Regression Analysis Example, Applications

1) Principal Component Analysis (PCA)

2) Factor Analysis (FA) Differences Between PCA and FA

3) Steps in PCA and FA, Software and Tools

Key Concepts in DOE, Steps in DOE, Types of Experimental Designs, Applications of DOE

Design of Experiments-II Key Concepts in Advanced DoE, Practical Steps in Advanced DoE Tools and Software for DoE, Applications of Advanced DoE

Kaizen, Kanban and Kaizen Blitz explanation, Summary

Theory of Constraint (TOC), Design Thinking,

Introduction and conceptualization of 5 S, Jugaad explanation

Risk-Free Solutions, Poka Yoke (Mistake-Proofing),

Key Components of a Control Chart, Types of Control Charts, Steps to Create a Control Chart Interpretation, Example

Control Plan, Control Tools, Implementation and Benefits

Key aspects of customer satisfaction, Methods to measuring customer satisfaction

Core Principles of ISO 9001, Structure of ISO 9001, Benefits of ISO 9001 Certification, Implementation Steps

Key Components of ISO 14001, Benefits of Implementing ISO 14001, Implementation Steps

Key Components of OHSAS 18001, Benefits of Implementing OHSAS 18001,

Introduction & concepts of Transition to ISO 45001, Implementing ISO 45001

Product Liability (Definition, Key Aspects), Customer Feedback (Definition, Key Aspects)

| Marks | Letter Grade | Description | Grade Point |

|---|---|---|---|

| 90 to 100 | O | Outstanding | 10 |

| 80 to 89 | A+ | Excellent | 9 |

| 70 to 79 | A | Very Good | 8 |

| 60 to 69 | B+ | Good | 7 |

| 50 to 59 | B | Above Average | 6 |

| 45 to 49 | C | Average | 5 |

| 40 to 44 | P | Pass | 4 |

| 00 to 39 | F | Fail | 0 |

| AB | AB | Absent | 0 |

Marks obtained by a student will be converted into grades at the time of result declaration.

Pankaj Singh Chauhan

Pankaj Singh Chauhan, with over 20 years of experience in IT, Service, and Manufacturing industries...

View More